The Importance of Seed Sowing in Modern Agriculture

Agriculture is the foundation of human society, and seed sowing is a necessary part in the farming process. Sowing is traditionally divided into three key steps: excavating the soil, putting the seeds at the correct depth, and covering them for protection. People have been sowing seeds by hand for many years.

It's an exhausting labor and one of the most difficult parts of farming. Obviously this does not lend itself to the high commercialization of modern agriculture, and the advent of the planter has changed that.

(Images from Pixabay)

What is a Seeder?

The seeder is an implement for planting or sowing seeds, it was designed to help simplify planting process. This advanced farming tool has multiple uses, including soil digging, seed sowing, soil covering, and fertilization. Seeders provide for ideal planting depth and planting space between seeds, resulting in a scientifically method of managing seed resources and enhancing crop production.

Types of Seeders

Small Scale Seeders

Small-scale seeders, often known as push seeders, are ideal for small to medium-sized farms. They are either manual or powered by small engines and are widely used in "non-grainization" nations such as as China, India, and Egypt.This type of seed sowing machine has the advantages of being flexible and lightweight, and also has the ability to sow seeds with high precision and at equal distances with digging nozzles. In addition, the small size of the push seeder allows the machine to adapt to most terrain structures, such as hills, plains, mountains, etc.

Seed Wheel Seeders:

The Seed Wheel Seeder is the most common type of push seeder. This sort of push seeder has a seed wheel that adjusts to different seed sizes. Typically, a machine will be set with seed wheels with varying hole sizes in order make a multi-purpose effect by switching the internal seed wheel components. This type of seeder can plant seeds such as corn, peanuts, beans, cotton, sunflower, melon, zucchini, wheat, rice, and other large-grain seeds. It is also suitable for small-grain seeds like sesame, beets, and rapeseed. This seed sowing machine is extremely adaptable and precise, making them excellent for a variety of seed kinds. Some models also have the ability to plant and fertilize simultaneously. Among the common push seeders, the replacement of parts of the seed wheel seeder is the most convenient. In addition, relevant replacement accessories are easy to find on the market. As a result, the seed wheel seeder has become the most popular machine on the market due to its high-cost performance, precision, and low need for servicing.

Spoon Type Seeders:

The Spoon Type Seeder has the simplest internal structure of any of the three types of push seeders. This type of machine employs an internal seed scoop for working with grain seeds or fertilizers. The spoon seeder, like the seed wheel seeder, often has seed scoops of varying diameters to correlate to particle sizes. However, due to its internal structure, the spoon seeder's accuracy is worse than that of other push seeders, and there are many cases of missing and numerous seeds. Farmers typically use this sort of seeder for crops that do not require accurate sowing of individual seeds, such as rapeseed, soybeans, etc. However, due to the simplicity of its design, the spoon seeder is the least expensive of the push seeders and can be used for fertilization. It is also a powerful piece of agricultural equipment.

Finger Clip Seeders:

The Finger Clip-type Seeders often contain metal clips with finger-like structures inside that clamp the seed particles and precisely put them into the holes in the digging nozzles. Known for their excellent precision, these seeders are suitable for bigger seeds, but they have higher maintenance costs and are not suited for small-particle seeds. And because this type of machine has high requirements for seeds when used, users usually need to use lead powder to wrap the seeds. Therefore, this is not friendly to the seed coat and soil environment, resulting in the finger-clip seeder being unpopular.

Large Scale Seeders

Designed for huge agricultural fields, these machines often work with tractors and are critical in countries with heavily mechanized farming industries, such as the United States and Canada.

Mechanical Seed Drills:

which use seed plates, dominate the large-scale seeder market. They are well-known for their ability to manage large-scale farming operations.

(Image by Carlos Barengo from Pixabay)

Pneumatic Seeders:

These innovative seeders use vacuum technology to gather seeds into an air chamber before shooting them into the soil by airflow.

(Image by Jan Nijman from Pixabay)

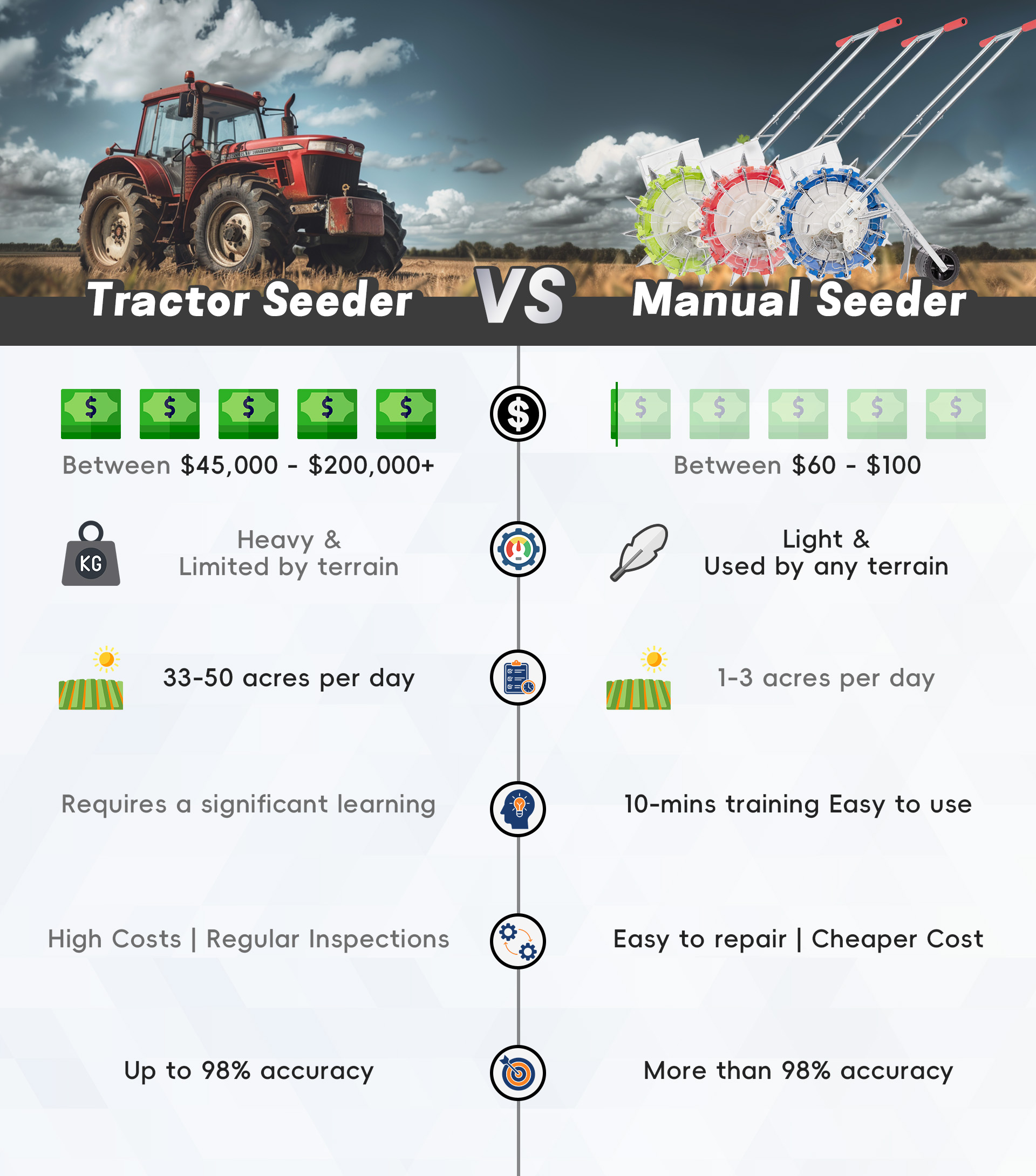

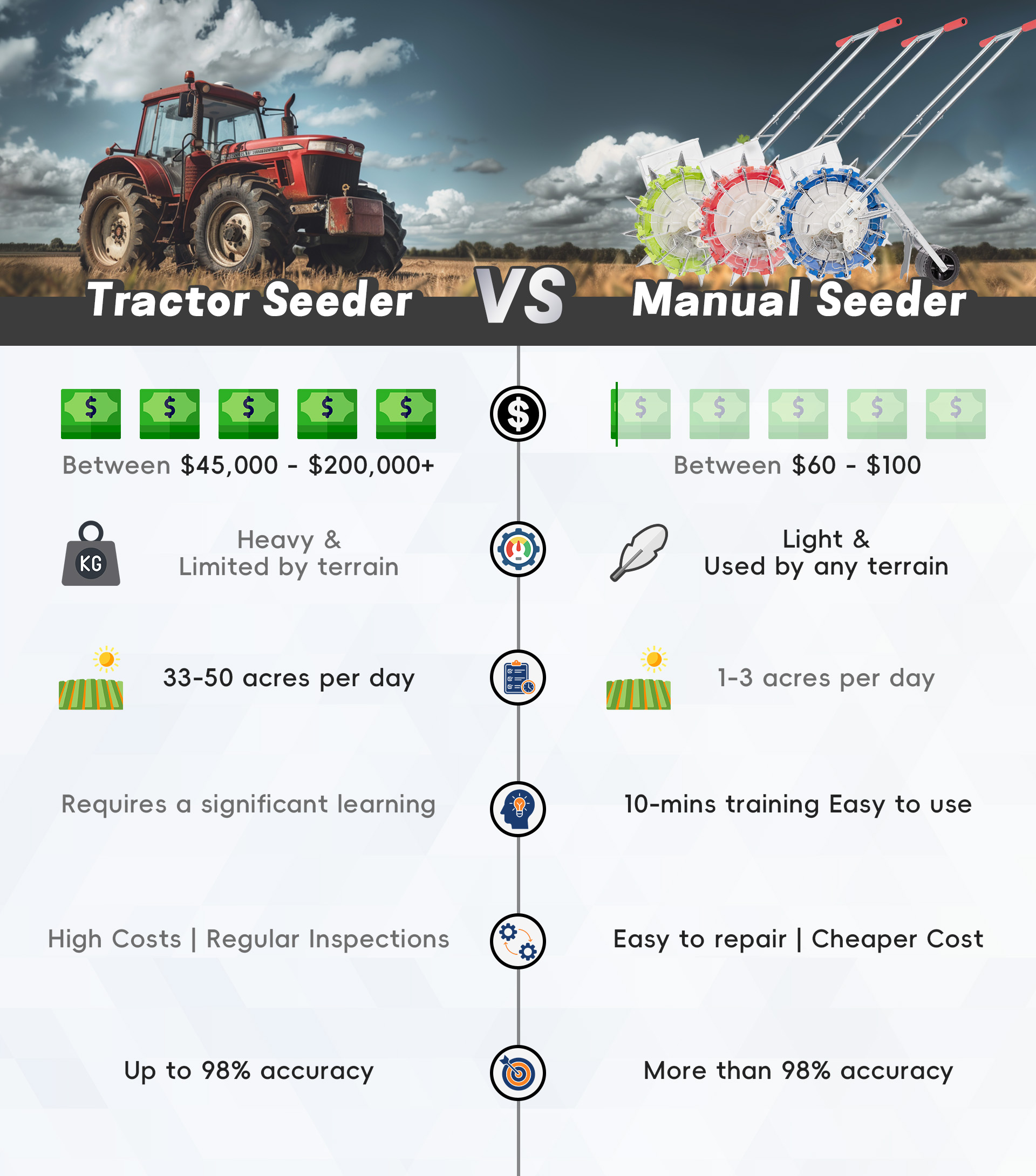

Pros and Cons of Small-Scale vs Large-Scale Seeders

Small Push Seeders

Advantages:

The cheaper cost: Because of its simple structure, Push seeders are both cheap and simple to repair. Their inexpensive cost makes them accessible to the vast majority of farmers.

Lightweight and portable: These machines are lightweight and easy to use, even by women, allowing farmers to seed up to 3 acres per day. Their small size makes them easier to transport and use in a variety of terrains.

Efficiency: While not as fast as larger machines, small seeders allow farmers to sow up to 3 acres per day, significantly lowering labor intensity and cost.

Precision: Small seeders achieve a sowing accuracy of more than 98%, ensuring that seeds are evenly disseminated in the soil for the greatest development.

Flexibility: Most Push seeders have adjustable depth and spacing settings, making them suitable for a variety of crops like maize, peanuts, soybeans, sesame, and sugar beets. They also come with multiple seed attachments, allowing for adaptable use with a wide range of seed types.

Ease of Use: Learning to use a little seeder is easy to understand. Farmers only need to follow the installation instructions, assemble the product, and push the machine to start sowing. It's a simple method that assures proper seed distribution and growth.

Disadvantages:

Manual labor: Push seeders, while more efficient than traditional methods, still require operation by hand, which means users have to direct the machine.

Large Seed Drills

Advantages:

High Efficiency: Large-scale seeders can cover large areas quickly and connect with smart devices to automate farm management.

High Precision: With a sowing accuracy of up to 98%, these devices enable farmers to precisely manage planting, fertilizing, and harvesting.

Disadvantages:

High Costs: Large seeders can be prohibitively expensive for farmers in underdeveloped nations to purchase and repair, making them unsuitable for smaller farms.

Complex Operation: These devices necessitate specialist training, which increases operational expenses and could restrict their application in areas with lower education levels.

Limited Flexibility: Due to their incredible size, these seeders are unsuited for fragmented or uneven fields.

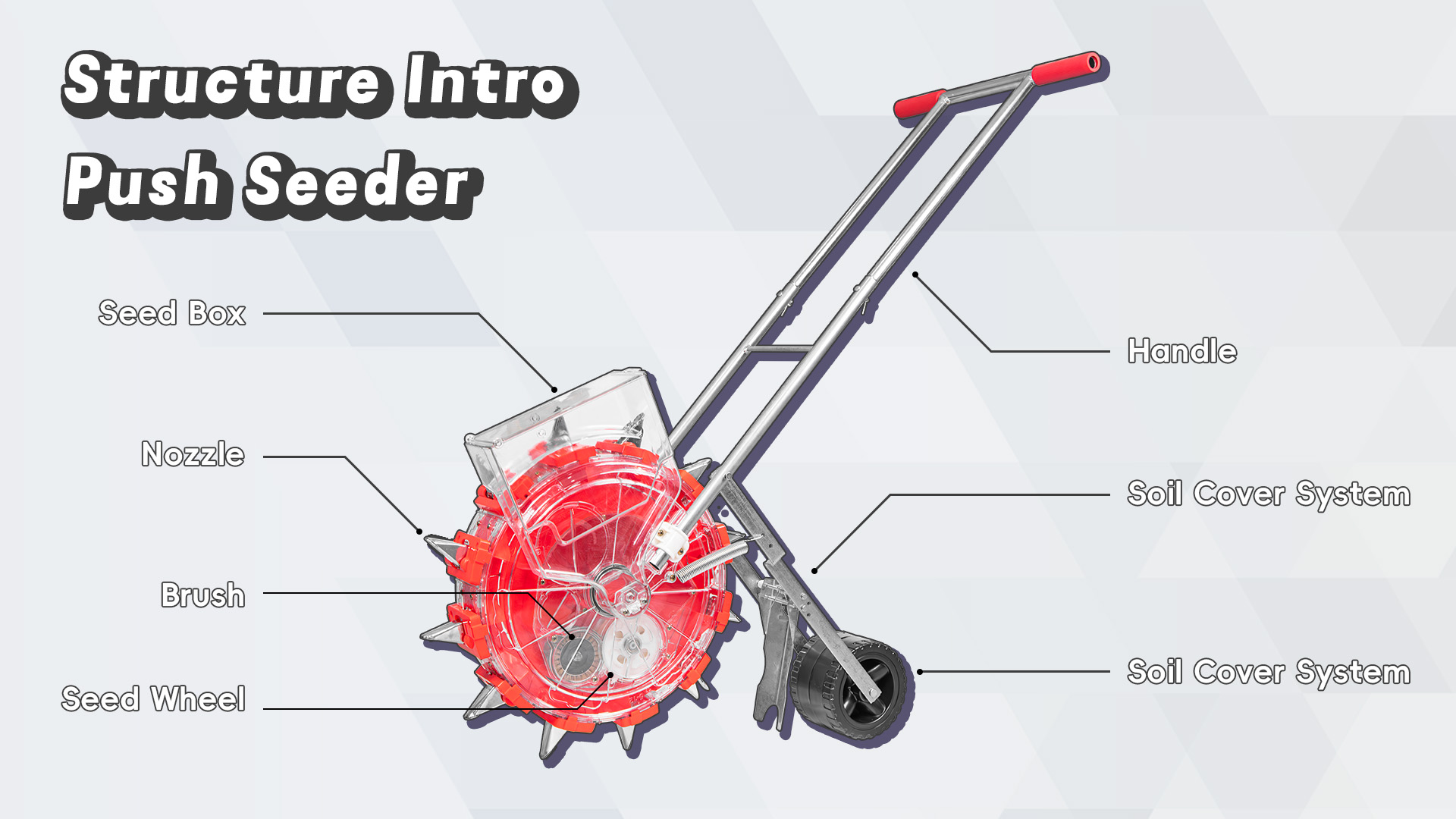

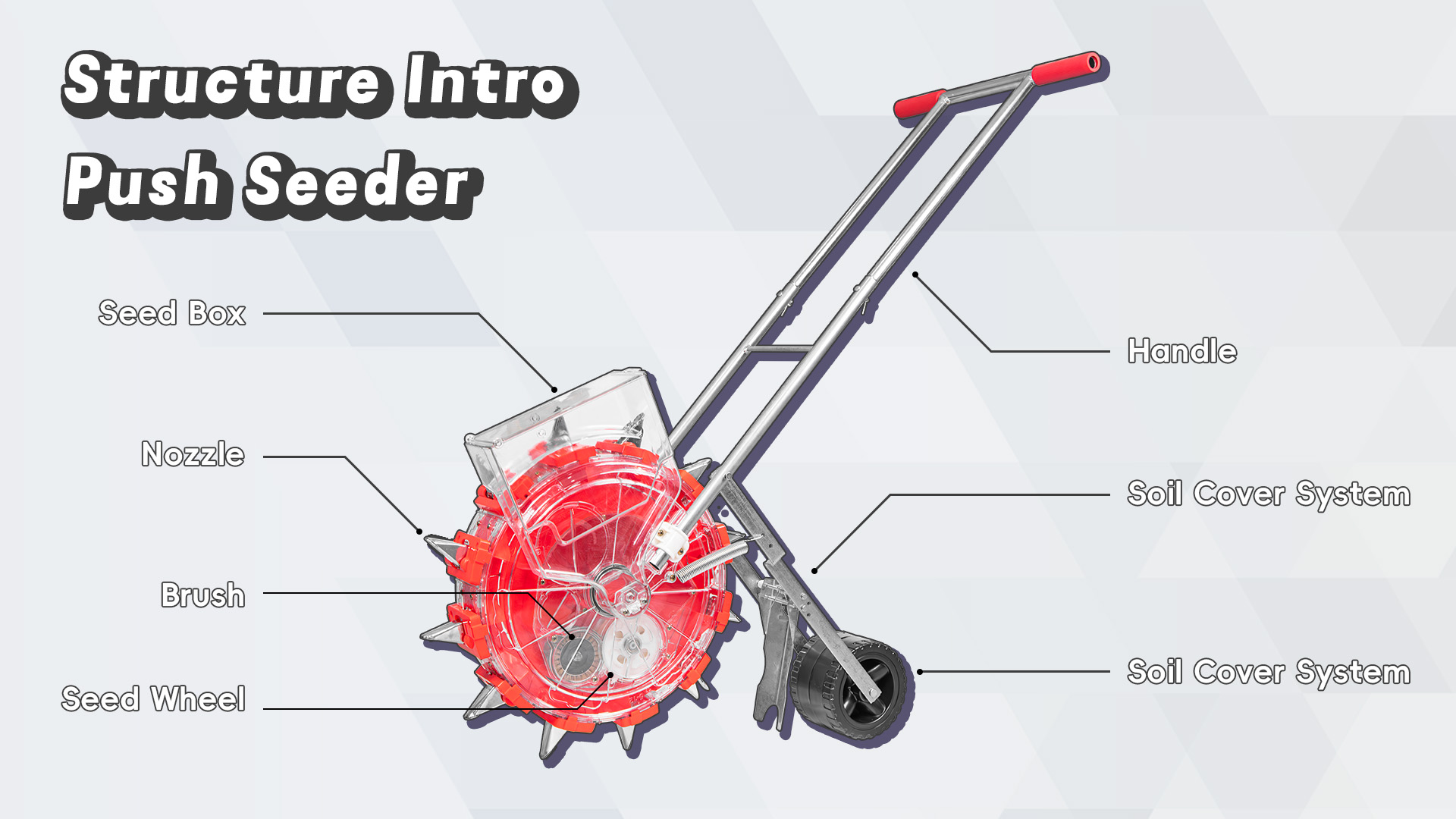

The Structure of Push Seeder

Push seeders (seed sowing machine) are typically made up of four major components:

Seed Box: An exterior container in which seeds are stored before entering the machine.

Main Machine Body: The core part of the seeder, including gears, brushes, seed wheels, and a series of soil-digging nozzles.

Handle: A two-part structure that allows the farmer to push and direct the machine.

Soil-Covering System: This part, which consists of a soil-covering frame and a wheel, helps cover the seeds with soil after they are planted.

How the Push Seeder Works

First, the farmer chooses the correct seed wheel or scoop to verify that each slot in the attachment can carry a single seed. After installing the machine and placing seeds in the seed box, the seeds pass through the gear system and fall into the seed wheel, which subsequently deposits them in the soil via the digging nozzle. Once the seeds are at the required depth, the soil-covering system ensures that they are covered and protected, allowing for a precise and easy sowing process.

Why Do Farmers Need Push Seeders?

Push seeders are vital for small and medium-sized farms as they are efficient, cost-effective, and environmentally friendly. These machines increase production, the quality of crops, and provide farmers with greater financial benefits. Farmers can increase the production of crops and simplify traditional sowing processes by using Push seeders.

Hand-push seeders offer a significant advancement towards modernizing agriculture and enhancing efficiency. Countries like China, Thailand, India, and Egypt can profit from this equipment, which allow farmers to enjoy the benefits of modern agricultural tools at a cheap cost.

Is the Push Seeder Suitable for You?

Haudin's hand-push seeders are suited for farmers who own at least two acres of land. If your soil is sandy or loose, these devices are ideal for efficient and precise sowing. With over 20 years of experience, Haudin offers high-quality, low-cost seeders with a global reputation. Our products are offered in over 40 countries, assisting farmers around the world to achieve modernized seeding at a low cost.

Contact us now for a free quote. As an OEM/ODM provider, we deliver tailored solutions to fit your specific requirements. Haudin will assist you in taking your farming methods to the next level.